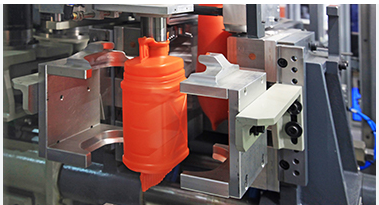

Rotomolding, also called rotational molding, is really a producing method employed to develop hollow products, such as tanks, storage units, and playthings. It calls for warming plastic-type material resin within a mildew that rotates on two perpendicular axes, allowing the plastic material to evenly cover the mold’s inside. After the plastic-type material has been cooled and solidified, the fungus is opened up, along with the finished item is taken away. This procedure gives numerous positive aspects, which includes layout mobility, expense-effectiveness, and sturdiness. In this article, we shall talk about the art of Rotomolding and how it might form your prosperity.

Website Physique:

Design Mobility: Rotomolding allows for sophisticated and elaborate models that other producing functions cannot accomplish. It may develop components with uniform walls thickness and accurate designs, which includes figure, angles, undercuts, and texturing. The mold may be personalized to match specific shapes and forms, and modifications can be produced easily without having more tooling charges. This measure of layout flexibility allows for product or service differentiation, brand name personality, and market attraction, causing elevated product sales and profit margins.

Price-Efficiency: Rotomolding is really a cost-effective approach because of the lower production and tooling charges. The molds and devices are less expensive compared to those utilized in shot molding or blow molding. Furthermore, it demands significantly less energy and labor, since it is a constant method that can generate a number of parts at once. The flexibility of Rotomolding enables producing large or small levels of items, based on need, without sacrificing top quality or persistence. This will make it an ideal option for startups, small businesses, and large businesses likewise.

Sturdiness: Rotomolded goods provide energy, affect amount of resistance, and longevity. The plastic resin applied during this process is generally polyethylene, which has very low denseness and high tensile power. This may cause the finished products proof against stress cracks, environment harm, and UV deterioration. Rotomolded merchandise is also recyclable, which makes them eco friendly and eco friendly. The durability of rotomolded goods assures client satisfaction, manufacturer loyalty, and history of high quality.

Apps: Rotomolding has an array of software, such as auto, aerospace, building, foodservice, healthcare, normal water treatment method, and a lot more. It could generate items such as fuel tanks, packing containers, kayaks, playground gear, waste containers, and health care products. The versatility of Rotomolding provides for the creation of products which satisfy certain industry specifications, like FDA concurrence, blaze retardancy, and substance level of resistance. The applications of Rotomolding are limitless, rendering it a valuable instrument for various sectors.

Future of Rotomolding: The way forward for Rotomolding is encouraging, as new components, technologies, and market segments emerge. Improvements in robotics, automation, and 3D scanning have streamlined the Rotomolding approach, decreasing lead occasions and improving accuracy. The introduction of bio-centered plastics has made rotomolded goods much more environmentally friendly and eco-friendly. Since the need for light-weight, resilient, and recyclable products keeps growing, Rotomolding will continue to be a workable choice for companies planning to form their success.

In short:

In In short, the art of Rotomolding gives several positive aspects for suppliers planning to design, produce, and marketplace higher-top quality goods. The flexibleness, cost-effectiveness, sturdiness, and uses of Rotomolding make it the important instrument for various market sectors. As the way forward for Rotomolding unfolds, we could expect it to keep to condition our success and give rise to an even more lasting and revolutionary world.